STC AEROSPACE

Delivering high-quality aerospace solutions with precision, innovation, and expertise.

Your vision, Our precision.

Turning visions from concept to reality with expert machining, cutting-edge technology, and a commitment to superior craftsmanship and quality.

Handlebox assembly

At STC Aerospace, we specialize in the precision manufacturing and assembly of Handlebox assemblies, producing 90% of the components in-house and assembling them with the highest quality standards. Our advanced machining capabilities allow us to hold tolerances within tenths (0.0001″), ensuring a perfect fit and seamless operation.

Hook assembly

The process starts with machining a solid block, adding two countersunk holes on each side, which serve as locators for our live centers on the lathe. The hook is then machined on a 5-axis CNC for complex contours and precision. The hinge block, which secures the hook, is dovetailed for stability and also machined on a 5-axis CNC for a precise fit.

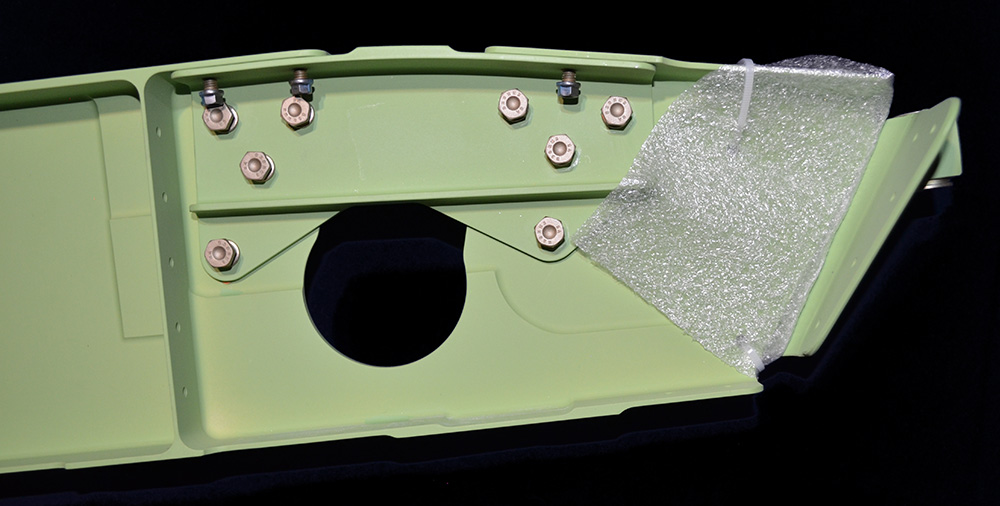

Beam assembly

The Beam Assembly at STC Aerospace consists of four precisely machined components, all manufactured in-house to ensure accuracy and consistency. These parts are bolted together to form a durable and high-precision assembly that meets aerospace industry standards.

Ensuring Quality

At STC Aerospace, quality is not just a requirement—it’s a core principle that drives our entire operation. From raw material inspection to final assembly verification, we employ advanced metrology tools, rigorous quality control processes, and AS9100-certified procedures to ensure every part meets the highest aerospace standards. Our ability to machine, inspect, and assemble in-house allows us to maintain complete control over quality and consistency.

In-House Assembly Capabilities

Our assembly department is equipped to handle a wide range of aerospace components, including:

Mechanical Assemblies – We integrate precision-machined parts, fasteners, and sub-components to create fully functional aerospace assemblies.

Riveting & Structural Assembly – Using pneumatic and manual riveting techniques, we assemble structural components with precision and durability.

Bushing & Bearing Installation – Press-fit and shrink-fit processes are performed with strict tolerance control, ensuring proper alignment and longevity.

Sealant & Adhesive Application – We apply aerospace-approved sealants and adhesives to meet environmental and operational requirements.

Final Testing & Inspection – Each assembly undergoes a rigorous fit, form, and function check to ensure performance and compliance with customer specifications and AS9100 standards.